Technical documentation

Data sheets are available for all standard products and provide specific details on item numbers, applications, materials, dimensions, approvals, etc.

Installation instructions are also available for a number of products as PDF files, as well as animations and videos of the installation process.

CE declarations, product certificates from LGA/TÜV Rheinland, etc., are also available for a wide range of products.

Technical documentation is found on the respective product pages under Standard Product Range. In addition, there is a collection of documentation files under Downloads at the top of the page.

Proper installation

Proper installation boosts the quality of the completed building. Faulty installation can have severe consequences. Particularly if the products being installed are in contact with rainwater.

This is why we offer training and guidance in the installation of our products. So, if you want to see how we define PROPER INSTALLATION, you can download installation instructions and films here from our website.

Link to installation instructions

Installation instruction

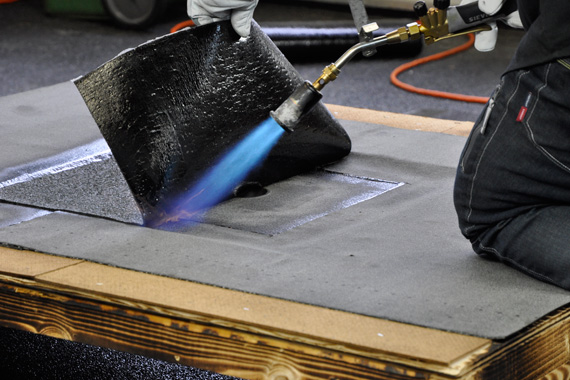

Membrane integration

The process of penetrating a roof surface creates a risk of leaks. This is why JUAL integrates roof membranes into products for drainage, ventilation, cable flashing, etc., in a controlled environment at the factory. This makes these critical penetration points watertight from when the products leave the factory, and the installation can be simple and reliable.

We integrate roofing membranes of many grades on stainless steel flanges as well as PVC and TPO membrane on coated steel plates. The adherence between roof membrane and flange is tested regularly pursuant to current standards.

Materials and surface treatments

We employ various types of sheet metal with different surface finishes and we employ bitumen and foil membranes. In addition, we also have a series of plastic products.

Drainage and ventilation products are made of stainless steel to maximise service life. Parts that are in contact with water and placed under the roof surface are made of acid-proof steel. We integrate all types of roof membranes to ensure the product’s watertightness from the factory.

Flashing profiles are typically made of aluminium or zinc sheet metal, but we can process all materials. We have large stocks of sheet metal in various grades and colours. If a colour is not in stock, we have the processed products painted in high-quality finishes. Typically in corrosion resistance class C3.

Product development

JUAL products are developed to meet the needs of the Danish and European roofing and facade industries and to conform to the requirements stipulated in international standards.

Ideas are converted into new products by our innovative, technically proficient employees. This often takes place in cooperation with our customers and on the basis of their needs.

Before releasing our new products, we test them at our Technology Centre where we optimise their ease of installation and test their functionality pursuant to international standards.

Tests and certifications

We test parameters such as flow capacities of drainage products and verify the adhesiveness of all types of membrane-integrated products. In cooperation with our suppliers of materials, we continuously ensure the compliance of our structural profiles with the requirements for UV and corrosion resistance classes.

The capacities of JUAL’s drainage products are tested pursuant to EN1253-2, which defines requirements for drainage capacity, product design, materials, etc. The materials included are also manufactured pursuant to current standards.

JUAL uses TÜV Rheinland in Germany for final testing and certifications.

Technology Centre

Testing and development takes place at our Technology Centre in Denmark where we test the capacity of our drainage products and other parameters. Our advanced testing facility enables us to simulate the conditions for which the products are designed. This includes heavy rain, backflow, varying drainage conditions, etc.

At the technology centre we can test and develop all our products for functionality, durability and, not least, ease of installation. We conduct ongoing test installations which result in improved products.

The technology centre is also the site of our internal and external product training. This is where we have facilities for working on all products under one roof.